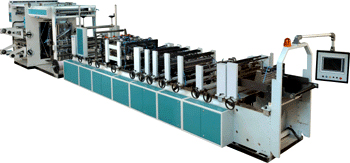

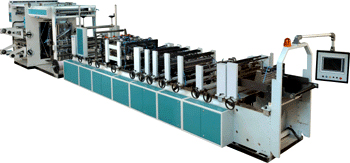

For Sale - PTP - 3410 - Stand Up and Zipper Pouch Making Machine

Reference Numbers

PTP - 3410Product

Stand Up and Zipper Pouch Making MachineManufacturer

XL Plastics, IndiaXL Plastics Model: SDP 704Z Delta

This Stand up and Zipper Pouch making machine is equipped with Multi servo system.

The machine is can handle 4 different films, all independently in register with the photo cell as it is equipped with different servo. They can be synchronized together to make 2 Stand up with zipper pouches together. You can also make a stand up or zipper pouch from 1 single sheet of 1400mm width or you can use different film for top and bottom and different for the bottom gusset.

Shaftless unwinders which are driven by AC motors with inverters drives and controlled by liner position sensors.

Each unwind film is positioned by separate ultra sonic sensor and web aligner. Each web is separately fed in to the machine by separate. Servo motors and registered by individual photocell for front back and side register. One vertical folding triangle for making stand up pouch from a single web.

Long sealing and cooling station - (lateral) with 500mm length of sealing jaw for 3 side seal / stand up seal servo driven up and down motion.

The machine consists of the following:

- 2 sets of stand up jaws

- 2 sets of zipper sealing jaws - for stand up and zipper pouches

- For 3 side seal pouch total 3 sets of long sealing jaws.

- Long cooling jaws - 500mm length with 4 sets of lateral cooling jaws.

- Cross sealing - 3 sets

- One set with upper jaw heating

- One set with lower jaw heating

- One set with both jaws heating

- Each of the above with individual servo motor for actuation. Cross cooling station - one set with servo motor actuation.

- One set trimming arrangement for side trim removal.

- One set of cross cutting station with servo motor actuation. Cutter stroke adjustable through PLC.

- Auto conveyor for batch collection after a preset count is reached the machine stops momentarily and the conveyor moves forward.

- Zipper insertion guides 2 sets for guiding the Zipper through the Zipper sealing jaws. Zipper feeding is by inverter drive with dancing roller

- PLC with touch screen 15" LCD display for controlling all the machine operation and for parameter settings.

- Each sealing and cooling station is controlled by individual servo motor and thus we can set the sealing time accordingly and to achieve optimum sealing time even at higher speed.

(For more details and picture, please see next pages)

For More Details Contact:

XL Plastics

Mr. Vivek Vora

Tel.: +91-265-2638125 / 2638026 / 2652118

Fax.: +91-265-2638661 / 2646716

E-mail: info@xlplastics.com

Website: http://www.xlplastics.com