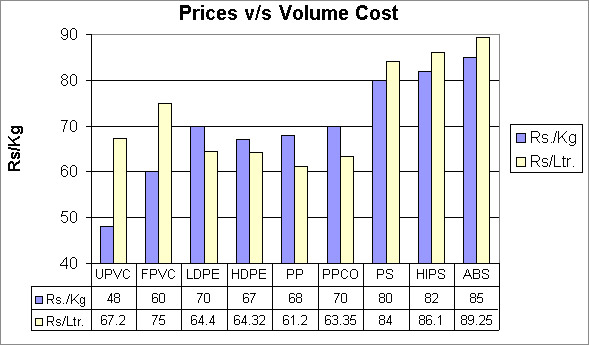

| 什么是数量成本? The Volume Cost of a raw material input is the purchase cost of a unit volume of the material. It is extremely important to understand the Volume Cost of Polymers and its additives as this plays a key role in their selection for a particular application. 体积cost (Rs./Litre) = Purchase Cost (Rs./Kg.) x Density (Kg./Litre or gm/cc) Let us examine the Volume costs of the major commodity Polymer families. 第一个水资源teristic of a polymer that a designer looks at before specifying it as the material of construction is its price. These vary from time to time, sometimes wildly, but tend to maintain their proportion vis a vis other polymers. Here are the recent prices of the Commodity thermoplastics (Ball park figures)

While it would look that UPVC is by far the cheapest Polymer, the natural question is that why does it have such limited applications in, say moulded products? Assuming that UPVC was as easy to mould as the other Commodity Thermoplastics, why is it not used in such widespread applications like buckets? At this point we have to look at one of the very important properties of Polymers, which many a time is overlooked. Fortunately this is not a property which changes with time.

The Density of a polymer is measured from a fully gelled and fused sample and should not be confused with Bulk Density, which is the apparent density of the granules or powder that the Polymer is sold as and is measured prior to processing. Bulk density has more relevance to rate of flow through hopper throat of the processing machine, tendency to bridge/stick and other handling and storage considerations. Bulk density can change depending on particle size/shape, but Density of a Polymer is constant. When the volume cost is plotted, a completely different picture appears. Polypropylene now becomes the cheapest  As we have taken the example of the household bucket, it is interesting to note that they were first moulded in LDPE in the early 60s. As HDPE became available in the late 60s, its lower volume cost was one of the reasons why there was a whole scale shift by bucket manufacturers to HDPE. Of course the better stiffness and warm water resistance of HDPE were major factors for the shift, but the lower Volume Cost helped. In the 90s, Polypropylene has also made inroads into the Bucket market, aided no doubt by its lower Volume cost, though its superior clarity, stiffness and temperature resistance were also factors. It is smart marketing which has positioned the clearer and stiffer PP Bucket as a premium product sold at higher prices than its HDPE cousin. As they say, �Pricing depends on marketing policy while Costing depends on facts�, and the fact is that the volume cost of the higher priced PP Bucket is lower than the HDPE one. That is to say that if PP and HDPE are injected into the same bucket mould volume, lesser amount of PP in Kgs would be required. It is a separate matter that the PP bucket mould would be different with perhaps a thinner wall to cash in on PP�s higher rigidity, but the reality of better volume cost remains. PVC was never in the picture because of its higher Volume cost. If its volume cost had been lower than the Polyolefins, ways and means would have been devised to mould it into buckets! Perhaps this example is too simplified as there are many factors which have to be considered to select the correct plastic for a specific application, but the point I am getting at is that Volume cost is a less understood but extremely important factor. Importance of Volume Cost to the Plastics formulator The consideration of volume cost is even more important when Polymers are compounded with additives. The density of the final product can change considerably especially when mineral fillers are added primarily to reduce costs. Volume cost and its implications are not properly understood by many entrepreneurs, formulators and persons undertaking cost reduction/value engineering. It is vital to understand its implications before embarking on cost reduction exercises. They are priced either per piece (Mouldings) or per unit length (Pipes, Cables, Tape). Thus the costing and pricing are for fixed Volumes. As the Plastic Raw materials are always purchased per unit weight, the tendency is to do cost calculations on a Per Kilo basis, and the finished product is priced accordingly to the weight per piece. However, in the marketplace, competitive pressures often force the entrepreneur to offer discounts to protect market share. The discount is normally a percentage of the existing selling price, which, in the majority of cases is the realization on volume basis. 如果按每公斤进行成本计算,则通过添加填充剂/扩展程序来降低成本的数量是原始配方成本的百分比。根据这个百分比,储蓄可以转化为价格降低。一段时间后,企业家意识到自己正在遭受损失,因为量减少的数量降低距离每公斤的成本远未达到。折扣所基于的成本降低,尤其是当矿物填充物是降低投入的主要成本时。所有矿物质填充物的密度都比大多数塑料高。 Rigid PVC Pipes is a prime example. The ease with which Calcium Carbonate can be loaded and processed by modern twin screw extruders has led to mindless loading of fillers in a desperate bid to reduce costs. The pitfalls are many as is illustrated:

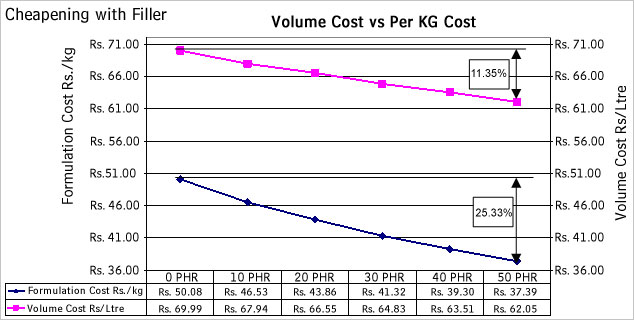

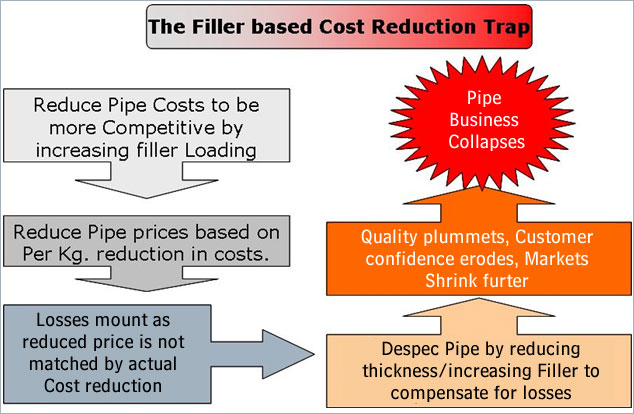

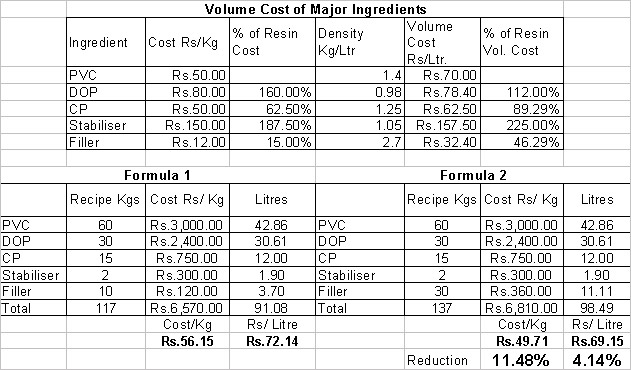

有趣的是,即使这些是理论计算,预测的密度也很接近实际测量的密度,而差异是第三个小数位的几个点。我们很少在第二个小数点找到错误。假设管道完全凝胶并且没有空隙,则预测的密度数字非常接近实际。有一些挥发性的损失,但是在管道配方中,这是一个低百分比。 图形表示显示了每公斤衡量成本和体积成本时成本降低的差异很大  通过添加50 PHR碳酸钙(不是不寻常的commercial grade PVC Water supply Pipe and in the non pressure applications like SWR) the expected cost reduction appears to be a healthy 25%. However, in actuality, the Volume cost has reduced only 11%. Such a high loading of filler not only ruins Pipe impact strength and pressure resistance, the wear and tear on costly twin screw equipment is severe. Thus it is not worth sacrificing so much of quality deterioration and machine life reduction for a mere 11% reduction in cost. This should be understood by all PVC pipe manufacturers and other sectors which rely on dense mineral fillers primarily for cost reduction. Of course nobody makes pipes with 0PHR filler, around 8-10 PHR filler is the optimum level for good quality pipe conforming to BIS 4985, and also acceptable Screw Barrel life, and it is heartening to note that most of the quality conscious PVC Pipe manufacturers have persisted with such formulations and have been successful in the long run. It is when higher loadings are resorted to for cost reduction that a vicious cycle starts. Let us say a manufacturer increases his Filler loading from 10 PHR to 40 PHR. Relying on formulation costing he expects a reduction of 15.5%. He reduces the prices of his pipes by 15% from his BIS 4985 price. However his cost per length of pipe has gone down only by only 6.5% (the Volume Cost reduction). Soon he finds out that he is losing money, so what is the next step? More filler loading coupled with decreasing the wall thickness of the pipe, deteriorating quality even further. And the downward spiral in quality and shrinking returns continues.  This is a most dangerous trend. Many Polymer applications in India have faced declining demand due to loss in confidence of the consumers because of repeated failures of poor quality cheap products. Examples are too numerous, and is most saddening to persons and companies who have worked so hard in establishing such applications. In the Pipe field itself, one can recall the hammering HDPE pipes took in the early eighties due to large scale failure of pipes made from scrap HDPE and sold to prestigious Government projects as prime grade pipes. While HDPE pipe market languished because of the bad name, PVC Pipes surged ahead. It has taken two decades for HDPE pipes to claw back to good volumes, which involved consistent quality and development of new application areas like Drip and Sprinkler Irrigation, Gas piping, Large diameter sewerage pipes etc. as well as consolidation in the core water supply sector with good quality pipe with second generation HDPE grades. A dangerous fallout of mindless filler loadings is when markets change from pricing per piece or in the case of pipes, per unit length of specified thickness to pricing on a per kilo basis. Such a change encourages higher filler loadings and should be resisted by all discerning manufacturers. In plastics, heavier does not mean more �Mazboot� (strong). Physical properties are seriously compromised in PVC products made heavy by excessive filler additions. 对于聚集素,情况有所不同。在这里,添加了诸如滑石粉和碳酸钙之类的填充剂,以提高对PP的刚度,或者诸如HDPE或PP Rafia胶带的抗纤维化的所需特性。将填充剂掺入聚芬蛋白是一个昂贵的过程,需要昂贵的共旋转双螺丝挤出机。填充聚烯烃的复合成本可以高达卢比。10-15/kg。,而在PVC中,干燥融合成本的增加可以忽略不计。填充的聚烯烃(10-40%)比基本聚合物更为昂贵,因为复合成本超过了较低的填充成本。数量成本急剧上升,但是对自动组件,模制家具和其他技术零件的刚度更好的要求是增加填充物的驱动力。仅在填充物水平超过50%的情况下,就像在填充物中,每公斤的成本低于聚合物成本水平,但数量成本将不利。因此,通常,填充物并不会像PVC那样自动导致使用聚芬蛋白节省成本。这就是为什么无法通过添加填充剂(例如在PVC)来廉价的聚烯管管道的原因,这是确定这一点的数量成本注意事项的原因。 Volume cost implications with Filled Polyolefins will be examined in a subsequent paper. Glass Filled Polymers is a special case with the fillers price sometimes exceeding the Polymer prices. It should be obvious that Glass filling is done purely to improve mechanicals. In Flexible PVC, considerations of Volume costs come into play. Large amounts of Plasticisers and extenders (Secondary Plasticisers) are used. The volume cost calculations are similar, though the contraction in volume in Flexible PVC compounds is a bit more because of volatile constituents in the liquid added. Here is a simple example of a soft PVC compound stabilised with a mixed metal Stabiliser/ESO mix. It is interesting to note how the relative costs of the other ingredients change in relation to PVC Resin when viewed from the Volume cost angle. Plasticisers like DOP which per kilo is much more expensive than resin has always been thought to be the reason why Plasticised PVC is costlier than RPVC. But DOP, for example, is not that costly from the Volume cost viewpoint. In fact when PVC prices had flared up, DOP was actually cheaper than Resin on a per liter basis.  同样,通过增加填充物的增加,预期的成本会大大侵蚀数量成本。 像流行的氯化石蜡家族这样的二级增塑剂的密度高于原发性增塑剂。更高的氯化,更高的密度和廉价效果较小。除填充剂外,CP是偏爱的成本降低工具。它需要相当大的技能来平衡与加法PHR选择的CP的氯化水平之间的兼容性,以实现有效的成本降低而不会损害质量。那些易于采取高填充路线的PVC处理器应暂停并重新考虑其策略。如此众多的PVC管道和轮廓挤出公司崩溃和关闭的商店的原因之一是,他们被陷入了这个恶性循环较高的填充物载荷 - 墙壁厚度的减小 - 产品故障 - 赔偿索赔,并被巨大的损失所困。还有其他降低成本的方法,不会影响质量并提供物有所值。PVC处理器应在上升到填充水平之前探索并用尽所有其他路线。 (Source Courtsey: Siddhartha Roy, Consultant, RoyPlasTech) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Previous Article

Next Article

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}