Introduction to Stabilisers:

Stabilisers:

PVC分子对热和光不稳定。加热PVC会导致聚合物链破裂,从而释放盐酸气体。HCL催化更多的降解,降解可能会爆炸,从而释放大量的腐蚀性HCl和其他有毒气体。暴露于紫外线辐射也可以分解聚合物链,但比热降解慢得多。

Heat Stabilisers:

To process PVC, it has to be stabilised against the action of Heat required at processing temperatures. Most Stabilisers contain metal elements which react with HCl and inhibit further degradation. They are Metal Salts, Soaps or Complexes. Stabilisation of PVC is a vast subject, and they are the second most important ingredient in UPVC Formulations and after Plasticisers in a Flexible PVC formulation. Some of the most important families are:

|

| Type |

Form |

PHR使用了 |

明晰 |

有毒的ity |

气味 |

Cost/Kg |

| Leads |

Powder |

2 -4 |

Opaque |

有毒的 |

None |

~ Rs 120-150 |

| Ba- Cd |

Liquid |

1.5 – 2.5 |

清除 |

非常有毒 |

Slight |

~ Rs 200 |

| BA -ZN |

Liquid |

2 - 3 |

清除 |

有毒的 |

Slight |

~ Rs 190 |

| Cd - Zn |

Liquid |

2 - 3 |

清除 |

有毒的 |

Slight |

~ Rs 220 |

| Ca - Zn |

Liquid |

3 -4 |

清除 |

无毒 |

Negl. |

~ Rs 250 |

| Tins |

Liquid |

0.5 -1 |

Crystal |

T & Non |

Strong |

~ Rs 350 |

| BA -ZN |

Liquid |

2 - 3 |

清除 |

有毒的 |

Slight |

~ Rs 190 |

The correct choice of stabilisers for the target application is best done in consultation with the stabilizer supplier and technical service cells of PVC Resin suppliers, However, as a guideline the following table would be useful.

稳定器应用领域:

| Type |

Heat Stability |

Main Applications |

Not recommended for |

| Leads |

Very Good, esp. long term. |

Cables, Pipes & Fittings, Sleeves, Profiles. Cheapest. |

清除Application. Can be toxic. |

| Tins |

Best |

Transparent tubings and sheeting, High quality Pipes, Medical |

Causes sulphide staining with Leads. Costliest Stabiliser. |

| Cd - Zn |

缓和 |

ROHS电缆,无毒。管道和挤压。 |

For high heat history. |

| Ba- Cd |

Good |

Leather Cloth, Calendared products, Footwear. |

Non Toxic applications |

| Cd - Zn |

缓和 |

Foamed Leather Cloth |

For high heat history. |

| Metallic Stearates |

低 |

Co-stabilisers with lubricating action |

Sole Stabiliser. |

Newer families of heat Stabilisers are being offered with the background of Heavy Metal environments contamination concerns. Organic Stabilisers and Calcium Zincs are in the forefront of this trend.

由于其成本相对较低和强大的稳定动作,铅稳定器历史上一直是最受欢迎的

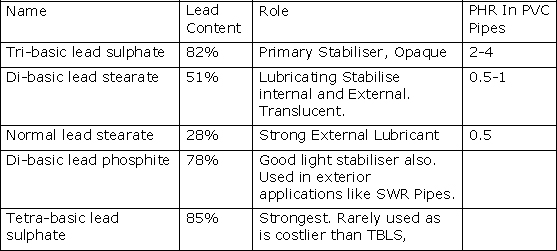

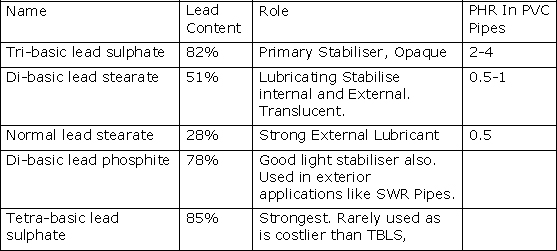

• Lead Stabilisers: The common Lead Stabilisers are:

o TBLS- Tri Basic Lead Sulphate. A strong heat stabiliser as it has about 80% PbO, the active ingredient in absorbing and neutralising the HCl before it gets liberated on heating. It is non-lubricating and is opaque, cannot be used in Transparent/Transluscent applications

o DBLS- Dibasic Lead Stearate. A Lubricating stabiliser very useful for lubrication at the mixing and metering zone of the extruder. Translucent.

o ls-硬脂酸铅。最弱的铅稳定剂。强大的外部润滑剂,尤其是在早期挤出阶段。半透明。

o There are other Lead stabilisers like Dibasic Lead Phosphite, used when Light Stability is important and Dibasic Lead Phthalate, used for high speed extrusions, but these are not being covered in this article, as they have niche usage.

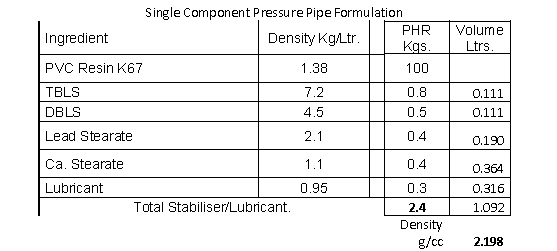

Calcium Stearate and Stearic acid are often used along with Lead stabilisers primarily to balance the Lubrication. CS is a weak stabiliser but an excellent internal lubricant, very effective in late stage lubrication at barrel discharge and die head. Stearic acid is a strong external lubricant, Excessive use can lead to screw slippage and poor gelation.

Lead Content of Lead Stabilisers.

One disadvantage that Lead stabilisation systems have is that a good, balanced formulations require a combination of all the Lead stabilisers plus Calcium Stearate and a few more lubricants. Other systems like Tins and Mixed metals are normally one grade of Stabiliser and one or two lubricants. With Leads, careful weighing of six or seven ingredients may be required, which requires skilled operation.

Lubricating Lead Based One Pack Systems

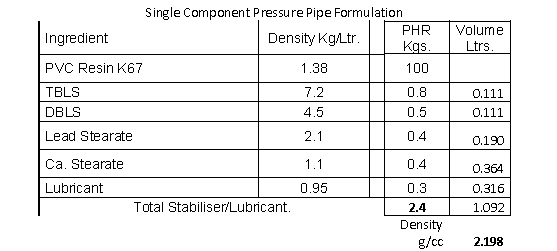

The Stabiliser mix for the high-volume PVC Pressure Pipes which I have used extensively in the past till the one packs came on the scene, is given in my article on Volume Costs, referred to in Page 6.

您会注意到,领先制造商提供的PVC管的常规等级的剂量建议起点约为2.2至2.4 PHR。这与上面的5-6个成分的剂量相匹配,并且是方便的一个包装系统的基础。

The initial one packs offered were premixed single component stabilisers. The desired quantity was weighed out into packets according to the amount of Resin charged per batch. This is in line with the practice followed inhouse, but separate weighing of 5-6 ingredients was prone to weighing inaccuracies, especially of the minor ingredients. The stabiliser manufacturers used to mix the one pack recipes in bulk, and the mix was then meter measured and packed in easy to use packets, say for 25 kgs. PVC, 50 kgs, etc.

There was a lot of resistance to this concept in the early eighties. My personal experience is that having formulated with single stabilisers for nearly a decade at Shriram and PRC (DCW), I was introduced to the convenience of One pack systems when I went to Kuwait. The One packs from Baerlocher GMBH were an eye opener, and I wanted to introduce the concept in India when I returned to India in 1978 and joined Waldies, a prominent Lead oxides and PVC stabiliser company.

At that time, PVC Pipe markets was starting to grow rapidly with the leaders like Wavin, Finolex, Garware and Chemplast using large capacity imported extruders, while most the others were equipped with the venerable Windsor RC-100. Remember, at that time, PVC Pipes of the popular sizes up to 110 mm were reserved for small scale, and only the RC-100 (meaning 100 lbs/hr, about 40 kgs/hr) could be afforded by many who were entering the field as small-scale industries.

当时,管道的PVC食谱是由工厂技术负责人控制的严密保护的秘密。我的朋友Ala和我本人的Anil Anand先生感到沮丧,他们正试图推动一个包装概念,我们发现技术负责人根本不感兴趣地改用一个预先构造的一包。这将严重降低他们对公司的重要性!!

There was another factor working against the type of efficient one pack systems available abroad in the early eighties. The RC-100s with their co-rotating screws and low outputs and high residence times, required higher dosages, sometimes 4-5 PHR and had to be formulated like single screw extruders recipes. As the PVC pipe industry had started with small diameter conduits, many single screw extruders were pressed into service for water pipe. Even Chemplast were using large single screw extruders as per their American processing DNA. Added to the higher stabilisation costs, expensive flow promoters were needed for single screw pipes to match the strength of pipes made on the new imported Counter Rotating twin screw extruders.

The industry rapidly shifted to the imported Twin Screw extruders from companies like Cincinnati and Kraus Maffei, Battenfeld etc., and as the Pipe market was booming because of the WHO funded drinking water projects. The extruders were actually airlifted, such was the demand. Later in the 80s and early nineties, with more number of modern high output extruders being the norm, the one pack concept started taking hold.

The next step from premixed powders was to safer handling, non-dusting forms. One big drawback with handling Lead Stabilisers in the factory is susceptibility to lead poisoning of workmen, if handling, housekeeping and dusting was not kept under control. Newer one pack delivery systems were developed by heating the mix to about 160C so that the Lubricants, Calcium Stearate, Lead Stearate and Dibasic Lead Stearate melted and formed a dough with the non-melting TBLS. The dough was then extruded into pellets or pressed and chipped into flakes. This form was much safer to handle and gradually found acceptance.

This has been further refined by Stabiliser manufactures who start with Litharge (PbO). They react this with carefully prepared proportions of Sulfuric Acid, Stearic acid and some other lubricants like Calcium Stearate and special waxes. On completion of the reaction, all the PbO is converted to TBLS, DBLS and LS as per the formulation proportions. The reactor discharges to a rotating drum, where the paste is cooled and flaked off.

非润滑一包领导者not have enough lubricants to coat all the solids in the mix and are sold as powders. They are widely used for applications like Cables & Wires, Profiles, both Rigid and Flexible sleevings, Injection Moulded fittings etc.

除PVC窗口概况和注射模制配件等特殊应用外,除了稳定剂和润滑剂之外,还需要更多的成分,例如撞击修饰符和流动启动子。

Window profiles require 3.5-5PHR impact modifier and 1.5-2PHR Flow Promoter. When this is sold as a package in a one pack, the dosage must go up by 5-7PHR, that is 2.4+5=7.4 and 2.4+7= 9.4PHR. The price of the one pack goes up as the additives are quite costly.

In Injection moulded fitting, which are processed on single screw extruders, a flow promoter needs to be added. At 1.5PHR addition, the One pack dose goes up to 4PHR. Again, the one pack will be costlier than the normal pipe one packs.

One packs can also be offered with properties like UV Resistance, Antioxidants etc. if required. The one pack manufacturers invest a lot on developing the right lubricant mix for an application and offer several grades for the same application of PVC pipes, like Normal, Filled, Highly Filled, Single or Twin Screw etc. Even refinements like Conical and Parallel screw suitability can be provided. The price of the One pack would vary with the special ingredients chosen.

Dosage and Pricing

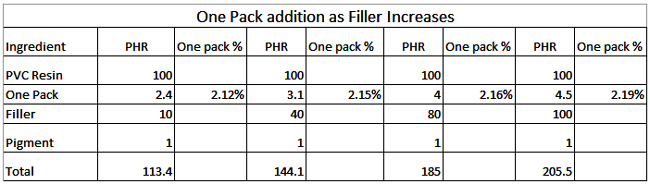

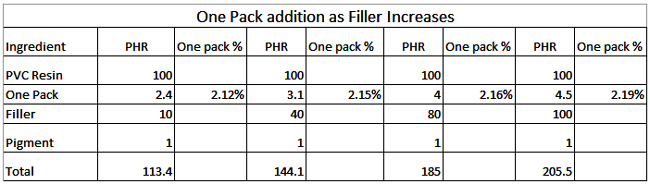

在竞争非常激烈的领域,PVC管,where the demand is for cheaper and cheaper inputs, CaCO3 fillers get added to the one pack to drop the price, However, to maintain the same stabilising efficiency, the one pack PHR has to be increased by the amount of inert filler added. This if 1 kg extra of filler is added, no doubt the price will go down, but the dosage goes up by 2.4+1=3.4. As most processors clamouring for cheaper one packs are making highly filled pipes, the one pack must be further boosted to maintain the same % of active PbO as in standard formulations.

The implications of adding fillers to cheapen One packs must be clearly understood, as Per Kg cost reduction is not the only factor.

这里有些例子:

在此示例中,我从标准的PVC管一包开始。如果使用了一个经济的填充物,则起点将为3.2 PHR,而不是2.4phr,并且在填充加载时达到100 PHR,则必须将加载几乎翻倍以使无故障操作。处理器的一个常见错误是坚持使用BIS管中使用的同一PHR,因为它们会增加填充剂。这会降低主动PBO含量和润滑平衡,并可能导致严重的处理问题。

A study has to be made by multiplying the One pack cost per Kilo and the addition level required in PHR to arrive at the stabilisation cost per 100 PHR Resin to determine how effective they are in cost reduction.

The amount of filler addition, especially at higher dosages will bring down the cost. But what is important is that whether the stabilisation cost is lower with the Standard or economical One packs.

Another factor which is important is the volume cost, for which the density of each ingredient is crucial. Anything added with a density more than PVC will increase the density (Like One Packs, Fillers, TiO2)

为了准确的密度计算和评估,必须知道所有成分的实际密度。一个包密度很重要,因为这个数字通常不在技术数据表中给出。

为了进一步清楚密度和填充加载的影响,请参阅我的文章

//www.esper-magazine.com/plastic-technical-articles/Volume-Cost-and-its-importance-in-Plastic-applications/1561

钙锌一包。

With the world moving away from Lead stabilisers. Calcium Zinc systems are becoming prominent for manufacturing Lead Free Pipes and where ROHS requirements are to be met.

硬脂酸钙是最常见的非铅稳定剂。但是,它的稳定功率非常低,更被视为一种非常有效的内部润滑剂,在模具头润滑方面起着重要作用,以使其平滑挤压和完成。

Calcium Soaps have been combined with Zinc compounds and the resultant Calcium Zinc Stabilisers have steadily improved in stabilisation efficiency. Driven by the intensive R&D of the stabiliser industry, Calcium Zincs are rivalling Leads in dosages, 3PHR vs 2.4PHR.

The lubrication systems are quite complex in Calcium Zinc systems for boosting the efficiency, so many of the Calcium Zinc grades are available as one packs and not individual components.

另一个主要的稳定系统是在美洲非常受欢迎的罐子,因为它们在单螺钉挤出机方面非常有效,这在美洲也转换为双螺钉之前是常态。

诸如Accaptide家族之类的锡稳定剂都是液体。这并不使其有利于一个包装输送系统。通常,锡稳定管是由单个组件制成的,润滑剂平衡对于出色的性能至关重要。锡稳定剂比铅更昂贵,但是由于它们的效率如此之高,据报道,挤出机顶部的加工机降低到具有强大的甲基罐头的0.3-0.5 PHR,并且与铅系统具有竞争力。

There are many suppliers of One pack systems, whose numbers have increased as one packs are now universally used by the huge PVC Pipes and Profiles sector

| Siddhartha Roy |

|

Mr. Siddhartha Royis a Chemical Engineer from IIT Kharagpur (1968). He has worked with plastics all throughout his career. He was actively involved in development of PVC markets and applications, especially Pipes and Fittings. He worked with Shriram Vinyls, PRC (now DCW) and Chemplast, manufacturers of PVC Resin & Compounds. He has managed a PVC Pipes & Fittings factory in Kuwait and helped Jain Pipes (now Jain Irrigation) set up their Pipe production facilities.

他在NASIK的VIP Industries领导研发,并且精通聚烯类,苯乙烯,聚酰胺和PC的处理。

He has been active in IPI activities and has delivered several Endowment lectures. He was recently awarded the Fellowship by the Governing council of IPI for his contribution to the Plastic Industry. |

|

{{comment.DateTimeStampDisplay}}

{{comment.Comments}}